In the spring of 2022, Oppo released their Oppo Find X5 Pro smartphone, which is made of their own MariSilicon X chip and it is an image chip. Single function chips, like image chips, video chips are not difficult to make; almost all brands can make their own single chips if they want. These chips work with the processor as the image chip integrates with the processor to optimize the performance of the image. Currently, almost all companies are trying to bring their own chips, but is it really possible? Big companies may want to work with their own processors, but the reality is not so simple. Building a chip is not only a difficult and challenging decision but it can cost billions of dollars. Let’s find out why smartphone companies can’t make their own processors.

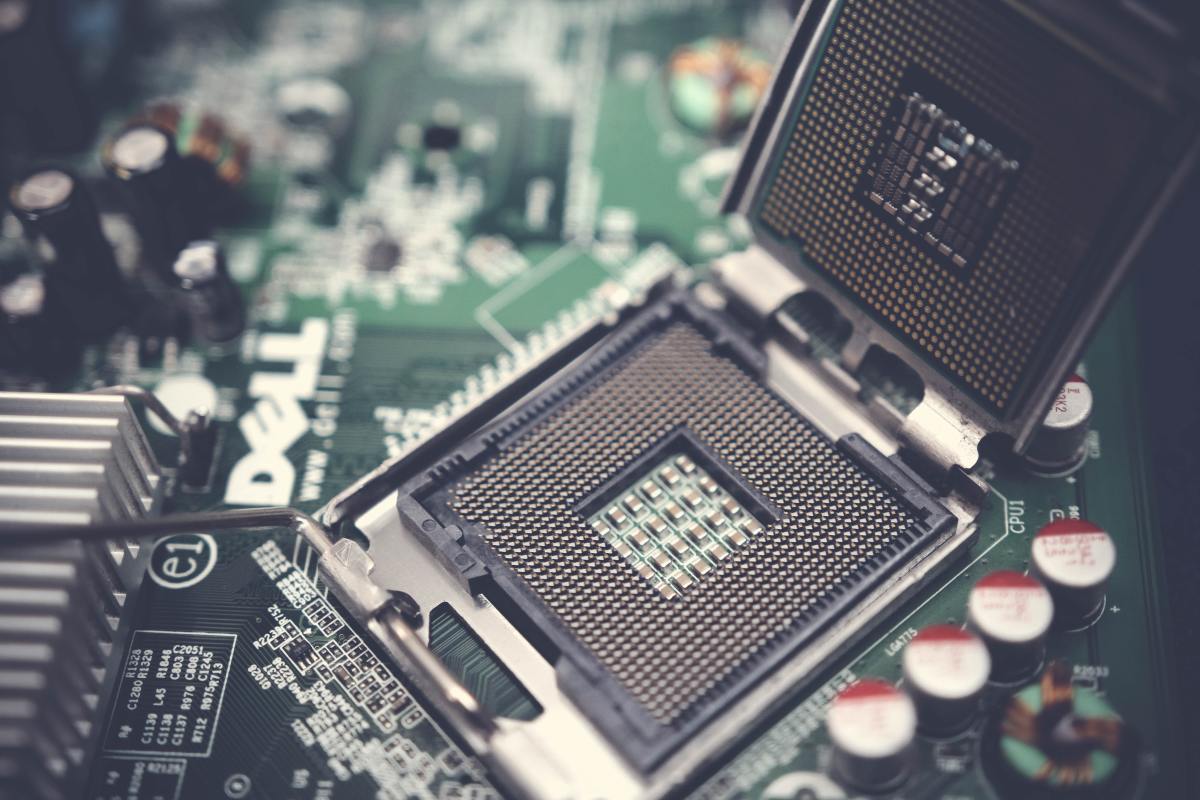

1. Processors Are a Complex Issue

Current processors do not have to be single function, they have to have a complete system on a single chip. The Apple A15 processor can be an example in this case. It’s not just a CPU, it also has Graphics Card (GPU), DSP, Image Processor (ISP), Wireless Baseband, AI Processor (NPU), Video Codecs, System Caches, and many more. Designing each part is not an easy task at all. After designing, combining them all is a very complicated matter. An example of this could be Baseband. Apple has been talking about Closed-Loop Ecology for years and finally came up with the M1 processor. However, in this processor they could not create a baseband that works 5G. After using Intel’s Baseband for two years, they again signed a contract with Qualcomm and the current iPhones use Qualcomm’s Baseband. Apple has been talking about a “closed loop supply chain” for years and finally came up with the M1 processor. However, in this processor they could not create a baseband that works 5G. After using Intel’s Baseband for two years, they again signed a contract with Qualcomm and the current iPhones use Qualcomm’s Baseband.

Intricate Design

The ability of companies to design modules is just one aspect. After design, these have to be combined with other function modules again. After module design:

Every part has to be connected with each part. There is a need to balance power consumption and performance. The correct data path is to be determined. The hardware layout and software design have to be done in a consistent manner. Nanotechnology must effectively control leakage and static power consumption. New technologies have to be used to optimize the process. High speed signals have to deal with issues like noise and compatibility.

You may understand how difficult it is to create a module or build a block. But what company can not maintain these issues? Of course you can, but you can’t do everything alone without the help of another company. Apple, Huawei, and Samsung can make processors, but with the help of other companies. Huawei has been working hard to make this chip since 2009. After 10 years of research and investment of billions of dollars, they have finally succeeded. However, the company is currently under some pressure due to various US sanctions, as they used some US technology to make the chip.

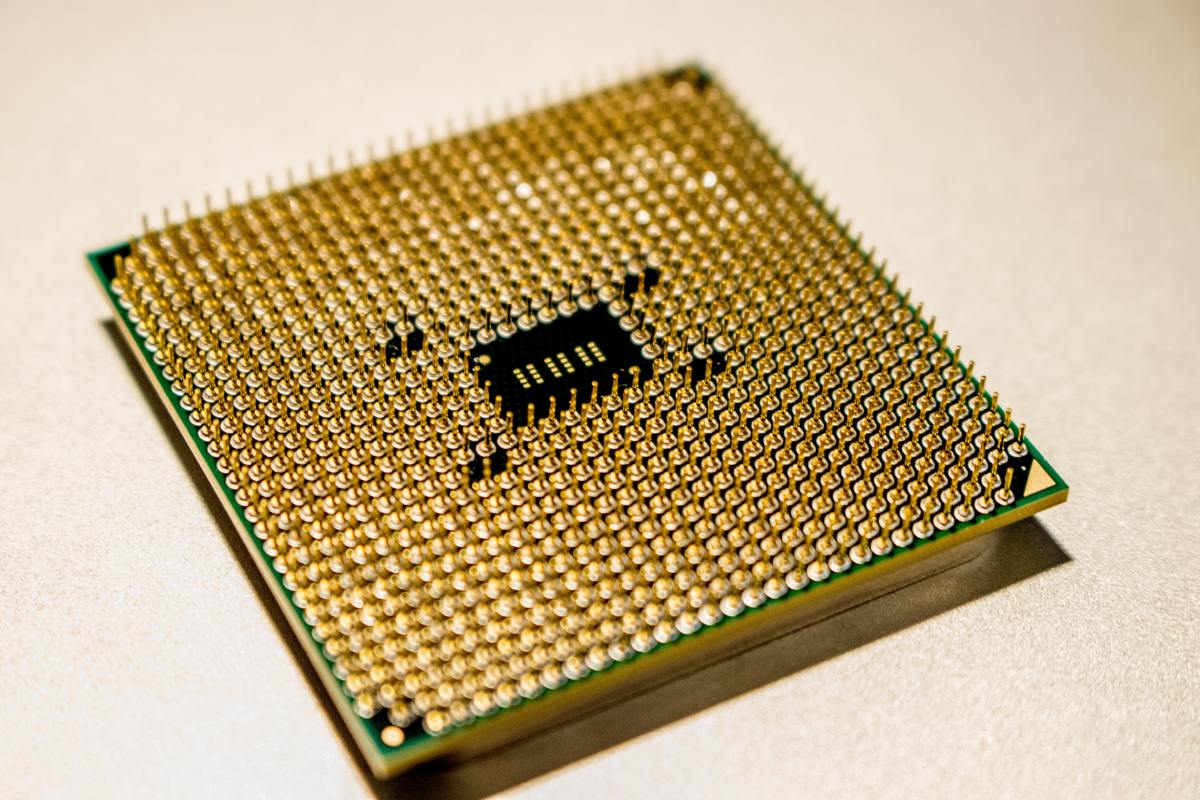

2. Processors Are Expensive to Make

Most companies that want to design a processor and enter the chip market do not have that financial capacity. Because many brands do not have the capacity to capitalize on it. If a company wants to make a chip, it is not easy to call a few people and start working. It takes a minimum of several hundred people to make a chip and must be an expert at the same time offering a hefty salary. Otherwise, no one will come to work so hard. In addition to human resources, you have to pay in Arm to make the processor. You also have to pay a license fee to buy Arm architecture and IP core. These are just some of the goal setting shareware that you can use. For example, you have to constantly pour money into development. As with the bugs in the program, there is a problem with the chip, these have to be fixed, tested every time, as a result it will cost a lot of money here. Some tests will be done through software simulation and for some tests, you have to make a processor and put it on real time phone and give trial. It may take a lot of chips to make it at the same time. This process is called “tape out” where the processors are given a trial. And this tape out must not be free. The 14nm process cost millions of dollars to tap out, while the popular 5nm process cost 50 million in 2021. How much will the mobile processor design cost? The question that comes to your mind is how many times does it take to tap out to make a chip? The answer is that it is impossible to say how many times it will take tape put. There may be some bugs that can’t be traced back to tape out. So this time you can guess how much money is needed to make the chip. A small example will make the point clearer. Huawei has invested 85.5 billion over the last 10 years behind their HiSilicon Kirin. Its investment in 2019 was. 20.08 billion. Finally, they were able to create the Kirin series SoC, which was able to compete with Apple’s Qualcomm.

3. Less Investment Results

Creating a smartphone processor has to go through multiple processes. You need to create different teams for different tasks. If all goes well with a few months of hard work and a few million dollars, you may get results, but very little. And smartphone companies don’t have that much patience and they don’t even want to make chips. Pop-up camera, under-screen camera, on-screen fingerprint sensor—all these work with the processor. Now if you want to add any one feature you need to build a new team, make huge investments and work hard for a few months.

Last Word

There is so much trouble in making processors, so much so that smartphone companies want to focus on making smartphones. They prefer to buy processors from companies like Qualcomm or MediaTek than to build processors themselves. This content is accurate and true to the best of the author’s knowledge and is not meant to substitute for formal and individualized advice from a qualified professional. © 2022 Md Ifran